Author Archives: admund

Check out some of the people who ride my boards

Thank you to all my customers who ride and give me feedback on my boards. Your feedback is key to my success in designing cutting edge boards.

Ahmed, Mauritius

Alistar, Indonesia

Arnim, German world traveler

Brian @ Cali Kites, San Francisco California

Carlos, Spain

Chucky Z, Mexico

MORE TO COME……….

How to get started on your new custom board

CONTACT….. A normal custom board order starts with an e-mail or phone call to me. If you already have an idea of what you want I can translate that design into your new board. If you are not sure what you need we can discuss your physical size, ability, riding style, etc……. I have built a very wide range of boards for a very wide range of riders, this allows me to understand your needs and design a board that will fit you perfectly.

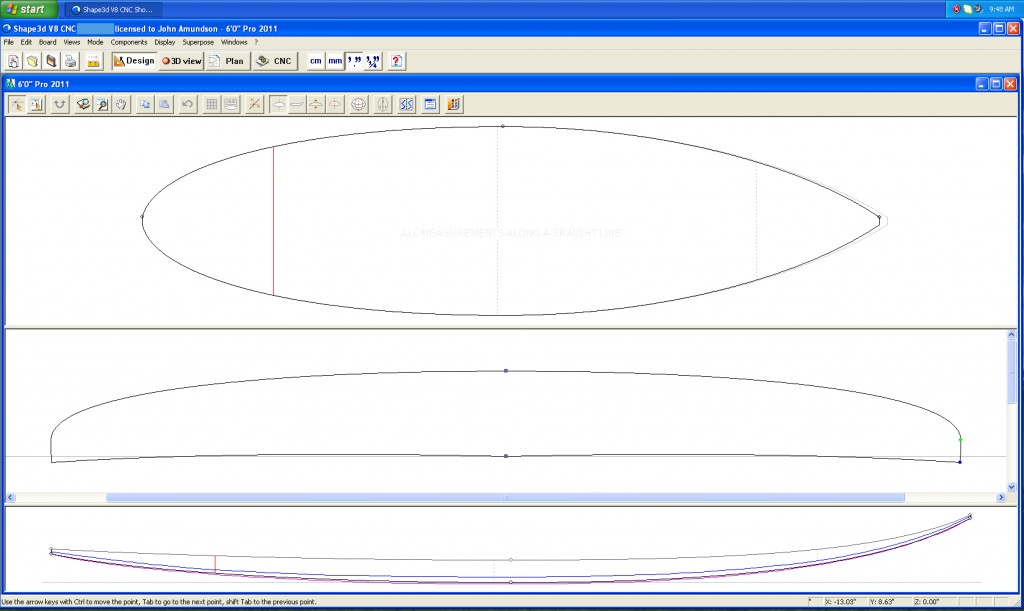

DESIGN….. After determining the best design for you comes designing. I design all custom boards on CAD (Computer Aided Design). This design program allow me to design your board within a fraction of an inch (or millimeter) with complete accuracy. I can then archive your design for future replication or modification. Every aspect of the board design (rocker lines, outlines, concave, thickness flows, rail shapes) can be manipulated and modified.

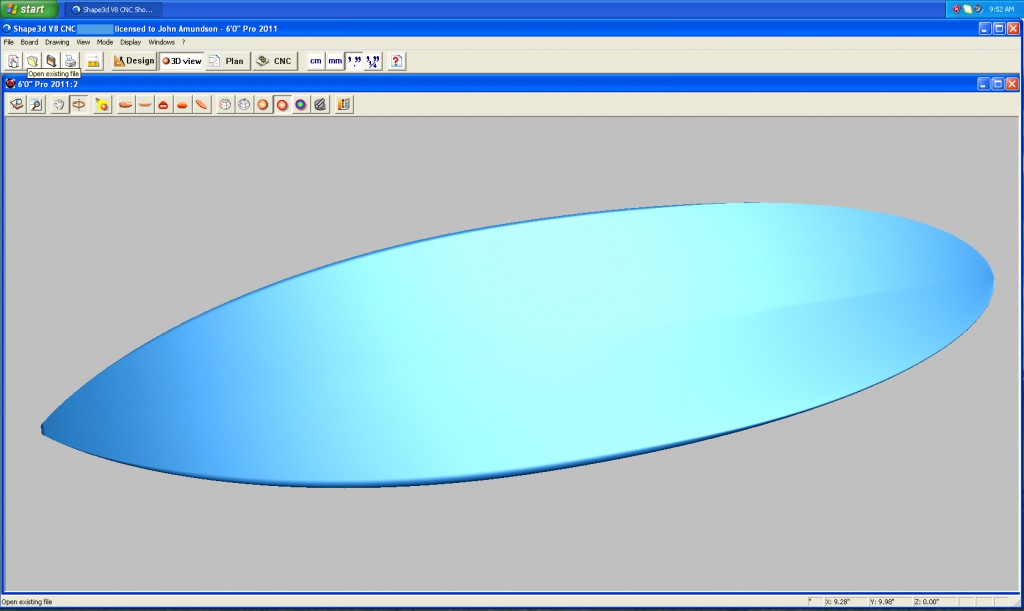

Viewing our CAD design in 3D allows for a virtual view of the shape.

CNC MACHINING….. Once your design is finished I machine your new board on my personal CNC machine. I built this machine a few years ago, it has been a huge asset to the development of my designs. Having it in house I am able to build a new idea, go out and test, and come back to refine that idea without any time delays. Another benefit is I can mill a design and if I am not satisfied I can re-design and mill again on the spot, no delays.

CNC MACHINING….. Once your design is finished I machine your new board on my personal CNC machine. I built this machine a few years ago, it has been a huge asset to the development of my designs. Having it in house I am able to build a new idea, go out and test, and come back to refine that idea without any time delays. Another benefit is I can mill a design and if I am not satisfied I can re-design and mill again on the spot, no delays.

HAND SHAPING….. After your new board has been milled it enters my shaping room. Here I fine tune and finish your board. I have been hand shaping since I was 15 years old (A very long time ago) and this hand shaping experience has given me the ability to visually assess all aspects of a design such as symmetry, esthetics, and (most importantly) functionality.